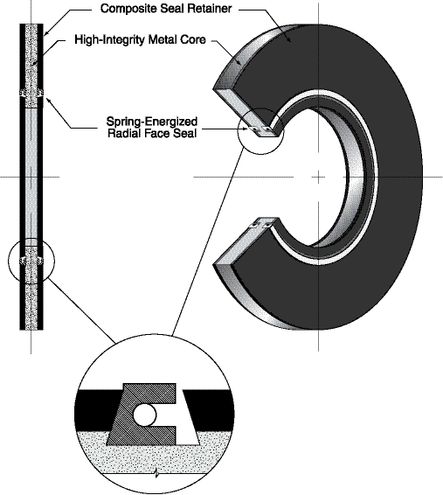

The Pikotek VCS gasket is a high reliability gasket used for both insulating and general sealing purposes in Very Critical Services. The gasket has a proven track record of integrity in aggressive sealing situations. The VCS is suitable in all services up to and including ANSI 2500# and API 15,000# classes. The VCS is designed for service where the cost of gasket failure cannot be tolerated. The VCS gasket consists of a PTFE (Teflon) spring-energized face seal, or an elastomeric o-ring, seated in an insulating laminate, which is permanently bonded to a high-strength metal gasket core. Due to its unique pressure activated sealing mechanism, the gasket requires far less bolt stress to seal than any other gasket. The VCS gasket inner diameter is exactly matched to the flange bore to eliminate turbulent flow and flange face erosion/corrosion. The seal elements are replaceable in the reusable gasket retainer.

Applications:

- Flange insulation in conjunction with cathodic protection.

- Insulation between dissimilar metals to prevent galvanic corrosion.

- Wellhead isolation from inter-connected flowlines.

- Mating mismatched ring-joint to raised-face flanges (VCS will seal in ring-joint, raised-face and flat face/slip-on flanges).

- Eliminate fluid trap corrosion between ring-joint (RTJ) flanges where high concentrations of CO2, H2S and other aggressive hydrocarbon media are present.

- Eliminate turbulence and flow-induced erosion between ring-joint (RTJ) flanges.

- Protect against coating impingement on coated flange faces.

- To seal between flanges subjected to vibration/cavitation (i.e., compressor stations).

Benefits and Advantages of VCS Flange Insulating Sets:

- Extremely high reliability sealing and insulating solution for all critical services makes VCS the gasket to use if you cannot afford gasket/insulation failure.

- Seals and insulates at all pressures up through ANSI 2500# and API 15000#.

- Unique stainless steel core bonded with high strength insulating laminate withstands severe service conditions including large bending moments, vibration, temperature and pressure cycling.

- Designed to withstand corrosive environments, including high concentrations of CO2, H2S, produced water, etc.

- Outstanding insulation properties for cathodic protection.

- Pressure activated seals provides high confidence sealing and eliminates costly leaks.

- Gasket is sized to the bore to protect flange faces from media-induced corrosion and flow-induced erosion. Prevents turbulent flow at flanged connections.

- Mitigates galvanic corrosion in dissimilar metal flanges.

- Insulating Kits (sleeves and washers) always include high strength double washers and full-length sleeves for maximum assurance against shorting.

- High strength laminate material resists failure due to excess compression (i.e., over tightening bolts).

- Spring energized Teflon seal provides radial load and encapsulation in the seal groove eliminates cold flow. This seal truly distinguishes the VCS from all other sealing systems.

- Available to match any flange specification (ANSI, API, BS, DIN, AS, others).

- Can seal mismatched RTJ Flange with Raised Face Flanges.

- Easy installation, make up and removal

- Flanges do not have to be spread as with Ring Gaskets. The VCS easily slips into place.

- Sealing system results in low required bolt loads. Less make up force is required resulting in less flange and bolt stress.

- Gasket is self-aligning and centering, quick to install, no special tools required.

- Maintenance free corrosion resistant design is resistant to deforming under load, which makes the gasket re-usable.

Tandem seal versions available – contact GPT engineering for size availability