Piping flange isolation kits and gaskets

TEKFLOW : OFFICIAL DISTRIBUTOR OF PIKOTEK® PRODUCTS

PIKOTEK® Flange Isolation Kits are designed to work in conjunction with our isolating gaskets to effect the complete electrical isolation of a flanged assembly. These kits consist of one full-length isolating sleeve, two isolating washers and two steel washers for each of the bolts in the flange assembly.

MAIN FEATURES

#Against : corrosion, electrostatic discharge, tension overload, flange leakage, explosion, fire and hostile environments

#Usable with all flange categories

#Adapts to seal rings and to operational conditions

#Increases the life of the seal rings

#Low clamping and compressive load

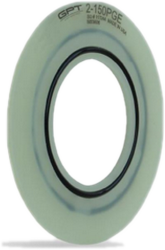

PGE™ SYSTEM ISOLATING GASKETS / KITS

The Pikotek® PGE™ is a low-pressure service isolation kit designed for electrical flange isolation and/or general sealing applications. This product was designed to give operators an alternative to the failure prone phenolic-based isolating gaskets. The PGE™ incorporates patented overlapping and offsetting seal grooves. The 1/8 » (3mm) design allows for easier installation and removal.

This system is suitable for use in raised-face and flat-face flanges in ANSI class 150 and 300 service (class 600 available depending on flange style, no RTJ). In addition to providing electrical isolation, the kit is excellent for isolating flanges made of dissimilar metals or where prevention of flange face corrosion is desired.

- GALVANIC CORROSION MITIGATION IN DISSIMILAR METAL FLANGES

- Superior sealing solution for low-pressure service : ANSI class 150, 300 and up to 600.

- Pressure-activated seals provide high confidence sealing

- Resistance to failure due to excess compression

- Overlapping seal groove : leak elimination

- Excellent isolation for cathodic protection systems

- Protection against media-induced corrosion and flow-induced erosion : gasket is sized to the bore

- Spring-energized Teflon seal provides radial load and encapsulation in the seal groove which eliminates cold flow. This seal truly distinguishes the PGE from all other sealing systems.

- Also available with a variety of elastomeric seals

- Quick and easy installation, make up and removal : no special tools required

- Less flange and bolt stress

- Self-aligning and self-centering gasket

- Maintenance-free, corrosion-resistant design

G-10 NEMA grade G-10 Glass-Reinforced Epoxy (GRE) laminate

- Compressive Strength: 66,000 PSI

- Dielectric Strength: 800 VPM Max.

- Continuous Operating Temp: 150° C / 302° F

- Water Absorption: 0.10

- Flexural Strength: 65,000 PSI / CW 52,000 PSI

- Tensile Strength: LW 40,000 PSI / CW 32,000 PSI

G-11 NEMA grade G-11 Glass-Reinforced Epoxy (GRE) High Temp. laminate material

- Compressive Strength: 50,000 PSI

- Dielectric Strength: 550 VPM Max

- Continuous Operating Temp: 200° C / 392° F

- Water Absorption: 0.20

- Flexural Strength: LW 57,000 PSI

- Tensile Strength: LW 41,000 PSI

The PGE™ is an excellent choice for isolating distribution lines and transport lines for gas, oil and water. Because the PGE™ has near zero creep relaxation, it performs well in heat exchangers, applications with high vibration or excessive thermal cycling.

VCS™ SYSTEM ISOLATING GASKETS / KITS

The Pikotek VCS™ is a high reliability gasket used for both insulating and general sealing purposes in Very Critical Services. The VCS™ gasket consists of a PTFE (Teflon) spring-energized face seal, or an elastomeric o-ring, seated in an insulating laminate, which is permanently bonded to a high-strength metal gasket core. Due to its unique pressure activated sealing mechanism, the gasket requires far less bolt stress to seal than any other gasket. The VCS gasket inner diameter is exactly matched to the flange bore to eliminate turbulent flow and flange face erosion/corrosion.

The VCS™ system can mate mismatched RTJ flange with raised face flanges. It is suitable in all services up to and including ANSI 2500# and API 10,000# classes. This system has a proven track record of integrity in aggressive sealing situations.

- CAN MATE MISMATCHED RTJ WITH RAISED-FACE FLANGES

- Turbulent flow at flanged connections minimized

- Resistance to failure due to excess compression

- Reliable sealing through a range of bolt stress

- Self-aligning and self-centering gasket

- Quick and easy installation, make up and removal : no special tools required

- Resistance to deforming under load

- Reduction of fluid entrapment, flow induced erosion and media induced corrosion between flange

G-10 NEMA grade G-10 Glass-Reinforced Epoxy (GRE) laminate material :

- Available in NIST G10CR process specification for materials used in cryogenic applications

- Compressive Strength: 66,000 PSI

- Dielectric Strength: 800 VPM Max.

- Continuous Operating Temp: 150 °C (302°F )

- Minimum Continuous Operating Temp: (minus) -128 °C (-200 °F)

- Water Absorption: 0.10

- Flexural Strength: LW 65,000 PSI / CW 52,000 PSI

- Tensile Strength: LW 40,000 / CW 32,000 (ASTM D638)

- Bond Strength: 2,300 lb.

- Shear Strength: 21,500 PSI

G-11 NEMA LI1 grade G-11 Glass-Reinforced Epoxy (GRE) laminate material :

- Compressive Strength: 50,000 PSI

- Dielectric Strength: 550 VPM Max.

- Continuous Operating Temp: 200 °C (392° F) Maximum

- Continuous Operating Temp: (minus) -45°C (-50°F) Minimum

- Moisture Absorption: 0.09

- Flexural Strength: LW 57,000 PSI

- Tensile Strength: LW 41,000 PSI

- Bond Strength: 2,200 lb.

- Shear Strength: 21,000 PS

The VCS™ system is an excellent choice for all the applications below :

- Flange insulation in conjunction with cathodic protection

- Insulation between dissimilar metals to prevent galvanic corrosion

- Wellhead isolation from inter-connected flow lines

- Valve connections

- Christmas Tree connections

- Pump connections

- Compressor connections

- Tanks and heat exchangers with sacrificial anodes to increase anode life

- Mating mismatched ring-joint to raised-face flanges (VCS will seal in ring-joint, raised-face and flat face/slip-on flanges)

- Elimination of fluid trap corrosion between ring-joint (RTJ) flanges where high concentrations of CO2, H2S, other aggressive hydrocarbon media are present

- Elimination of turbulence and flow-induced erosion between ring-joint (RTJ) flanges.

VCFS™ SYSTEM ISOLATING GASKETS / KITS

The Pikotek VCFS™ adds fire service capability to the standard Pikotek® VCS design through the use of a PTFE spring-energized primary sealing element and an E-ring secondary seal, seated in an insulating laminate and permanently bonded to a high-strength metal core, creating a fireproof gasket. The VCFS™ fire resistant gasket combines proven sealing performance in aggressive environments with the capability to pass the API 6FB, 3rd Edition fire test.

The VCFS™ consists of a PTFE spring-energized primary sealing element and an E-ring secondary seal, all seated in a high-strength metal core upon which an insulating laminate is permanently bonded. Due to its unique pressure activated sealing mechanism, the gasket requires far less bolt stress to seal than other gasket types. In addition, the engineered E-ring will serve as a secondary seal during normal operation and the primary sealing element during a fire. This system is suitable in all services up to and including ANSI 2500# and is offered for ring type joint (RTJ) flanges from 6”- 24” and raised face flanges from 2”-24”.

- CAN MATE MISMATCHED RTJ WITH RAISED-FACE FLANGES

- Turbulent flow at flanged connections minimized

- Resistance to failure due to excess compression

- Reliable sealing through a range of bolt stress

- Self-aligning and self-centering gasket

- Quick and easy installation, make up and removal : no special tools required

- Resistance to deforming under load

- Reduction of fluid entrapment, flow induced erosion and media induced corrosion between flange

- Ring type joint (RTJ) flanges from 2”- 36” (50mm – 920mm)

- Raised face flanges from 1”- 36” (25mm – 920mm)

- Compressive Strength: 66,000 psi

- Dielectric Strength: 800 VPM

- Water Absorption: 0.10

- Tensile Strength: LW 40,000 psi / CW 32,000 psi

The VCFS™ system is an excellent choice for all the applications below :

- Fire-safe flange insulation in conjunction with cathodic protection

- Insulation between dissimilar metals to prevent galvanic corrosion

- Wellhead isolation from inter-connected flow lines

- Valve connections

- Christmas Tree connections

- Pump connections

- Compressor connections

- Mating mismatched ring-joint to raised-face flanges (VCS will seal in ring-joint, raised-face and flat face/slip-on flanges)

- Elimination of fluid trap corrosion between ring-joint (RTJ) flanges where high concentrations of CO2, H2S, other aggressive hydrocarbon media are present

- Elimination of turbulence and flow-induced erosion between ring-joint (RTJ) flanges.

- Sealing of between flanges subjected to vibration/cavitation.

VCS ID™ SYSTEM ISOLATING GASKETS / KITS

The VCS ID™ gasket consists of a concave PTFE Inside Diameter (ID) seal and a PTFE spring-energized face seal, or an elastomeric O-ring, seated in an insulating laminate and permanently bonded to a high-strength core. The VCS-ID (Inside Diameter) Seal introduces an internal, machined PTFE seal at the bore of the existing VCS design platform.

The Pikotek VCS ID™ is an isolating system that provides the highest integrity electrical isolation as well as chemical resistance. Because the thickness of the inner PTFE seal is the same as the gasket thickness, the formation of an electrical bridge caused by conductive sediment build-up between the gasket steel core and the flange face is eliminated. The use of a patented interlocking mechanism ensures an extremely tight seal at the bore and resistance to effects from internal pressure or aggressive media.

- Great for :

> installations where electrical isolation testing is performed shortly after hydro-testing

> use in high chloride applications that could cause stress corrosion cracking with a stainless steel core

- Larger gap between flanges for better resistance to conductive sediment build-up

- Eliminates the need for exotic metal cores that match the exotic metal flange material

- Available with G-11 carrier for 200°C / 392°F

- Dual seal nominal pipe standard size in 6” and up.

- Larger than the pipe bore so that under compression it matches the pipe bore

The VCS ID™ system is an excellent choice for all the applications below :

- Applications with chemicals that would chemically attack GRE

- Installations where electrical isolation testing is performed shortly after hydro-testing

- Creates greater gap for greater electrical resistance

- Great for use in high Chloride applications that could cause Stress Corrosion Cracking with a stainless steel core

- Eliminates the need for exotic metal cores that match the exotic metal flange material

- Available with G-11 carrier for 392°F / 200°C»Dual Seal nominal pipe size in 6” and up are standard

Can simplify the hydrotest process

- Temperature rating:392°F/200°C

- Compressive strength: 66,000 psi (G-10)

- Dielectric Strength Volts/Mil : 800 (G-10)

- Tensile Strength: LW 40,000 psi / CW 32,000 psi

VCXT™ SYSTEM ISOLATING GASKETS / KITS

The VCXT™ gasket stands for a Very Critical eXtreme Temperature isolation set, a serrated, machined metal core insulating gasket faced with high-temperature THERMa-PUR™, sleeves, washers, metal backing washers and a Garlock 5500 spacer ring.

The VCXT™ high temperature flange insulation sets create a seal and maintain electrical isolation across a wide range of seating stresses and flange classes in elevated temperature service. They can be used in load compromised connections; such as damaged and/or lined flanges and also heavily bolted connections where significant gasket stresses may be generated. The insulating gaskets and washers have been designed and developed for use in standard pipeline flanges where both cathodic protection and high integrity sealing are required at elevated service temperatures.

- Main benefits

> Highest temperature rated isolating product available

> Firesafe per API 607 and API 6FB testing

> A better option for steam applications than GRE

> Sizes available ½” – 24” NPS > Wide range of chemical resistance - THERMa-PUR™ faces, a proprietary high temperature sealing material

> Exceeds temperature capability of traditional vermiculite or glass/epoxy insulation sets – 770°F (410°C)

> Suitable for sealing across a wide range of chemicals (pH 0-14) and sweet and sour gaseous and liquid hydrocarbons - A standard 316L core and washer metallurgy NACE (MRO175) compliant.

- High compression characteristics achieve strong seal over wide range of flange surface finishes

- Better handling/shipping integrity than mica or vermiculite based products

The VCXT™ isolation set, from the VCS™ family, is an excellent choice for all the applications below :

- Fire-safe flange insulation in conjunction with cathodic protection

- Insulation between dissimilar metals to prevent galvanic corrosion

- Wellhead isolation from inter-connected flow lines

- Valve connections

- Christmas Tree connections

- Pump connections

- Compressor connections

- Mating mismatched ring-joint to raised-face flanges (VCXT will seal in ring-joint, raised-face and flat face/slip-on flanges)

- Prevents fluid trap corrosion between ring-joint (RTJ) flanges where high concentrations of CO2, H2S and other aggressive hydrocarbon media are present

- Eliminate turbulence and flow-induced erosion between ring-joint (RTJ) flanges.

- A better option for steam applications than GRE

- Operational pressure range : Full vacuum to ASME B16.5 1500# API

- Maximum Operating Temperature Range : -328°F to 770°F (-200°C to 410°C)

- Dielectric Strength (ASTM D149a) : 3.937 kV/mm

EVOLUTION™ ISOLATION GASKET – THE FUTURE OF FLANGE ISOLATION

EVOLUTION™, the best available technology for pipeline isolation, comes from a long line of success, Pikotek® PGE™ ⅛” (3mm)design, Pikotek® VCS high-strength stainless steel core, Pikotek® VCFS firesafe gasket, Pikotek® VCS-ID™Concave GYLON® Inside Diameter (ID) seal. EVOLUTION™ incorporates all these benefits into one complete and robust package. The handle helps ensure accurate alignment during installation and includes product information for traceability

EVOLUTION™ is a patent pending product that is the first of its kind to be a fully encapsulated isolating gasket. The thinner, ⅛” (3mm) design minimizes the difficulties often encountered while attempting to install thicker isolating gaskets. The total encapsulation allows the gasket to be hydro-tested and kept in the pipeline with virtually no loss in isolation properties. The coating is a GPT proprietary material that is extremely abrasion and impact resistant. The coating is also chemically resistant to attack by H2S, steam, CO, CO2and other chemicals often found in oil and gas pipelines. EVOLUTION™ has passed API 6FB fire testing in multiple sizes and pressures. Since EVOLUTION™ has no laminations, it’s able to withstand high pressures with no ill effects unlike GRE gaskets which are prone to delamination. Furthermore, EVOLUTION™ does not have the permeation issues that plague GRE gaskets.

> Only three millimeters (1/8 inch) thick

> Thinner profile helps make installation easier and more accurate

> High dielectric strength

> Eliminates expensive exotic cores due to the fully encapsulated coating

> Rated to 500°F (260°C)

> Fire safe – provides the added security of knowing that the gasket has passed the API 6FB, 3rd Edition Fire Test in multiple sizes/classes

> High pressure – extremely high pressure capability

> Resistant to typical oil and gas chemicals, in particular H₂S, CO, & CO₂

> Impermeable seal and encapsulated carrier eliminates the need to replace gaskets following hydro-testing

> Larger than the pipe bore so that under compression it matches the pipe bore

> The handle found on the EVOLUTION® allows each gasket to be holiday tested during manufacturing to insure strong isolation performance in the field

> Helps ensure accurate alignment during installation

> Provides traceability and identification for the product

- Fire-safe flange insulation in conjunction with cathodic protection

- Insulation between dissimilar metals to prevent galvanic corrosion

- Wellhead isolation from inter-connected flow lines

- Valve connections

- Christmas Tree connections

- Pump connections

- Compressor connections

- Mating mismatched ring-joint to raised-face flanges (EVOLUTION® will seal in ring-joint, raised-face and flat face/slip-on flanges)

- Eliminate fluid trap corrosion between ring-joint (RTJ) flanges where high concentrations of CO2, H2S and other aggressive hydrocarbon media are present

- Eliminate turbulence and flow-induced erosion between ring-joint (RTJ) flanges.

- To seal between flanges subjected to vibration/cavitation (i.e., compressor stations).

- For slip-on flanges and coated flanges, please contact GPT engineering

- Temperature rating:392°F/200°C

- Water absorption:.2%

- Compressive strength:(.5”) : 63,000 psi

- Dielectric Strength Volts/Mil (Short Time) : 1,100